SPEE3D opens US 3D print applications centre

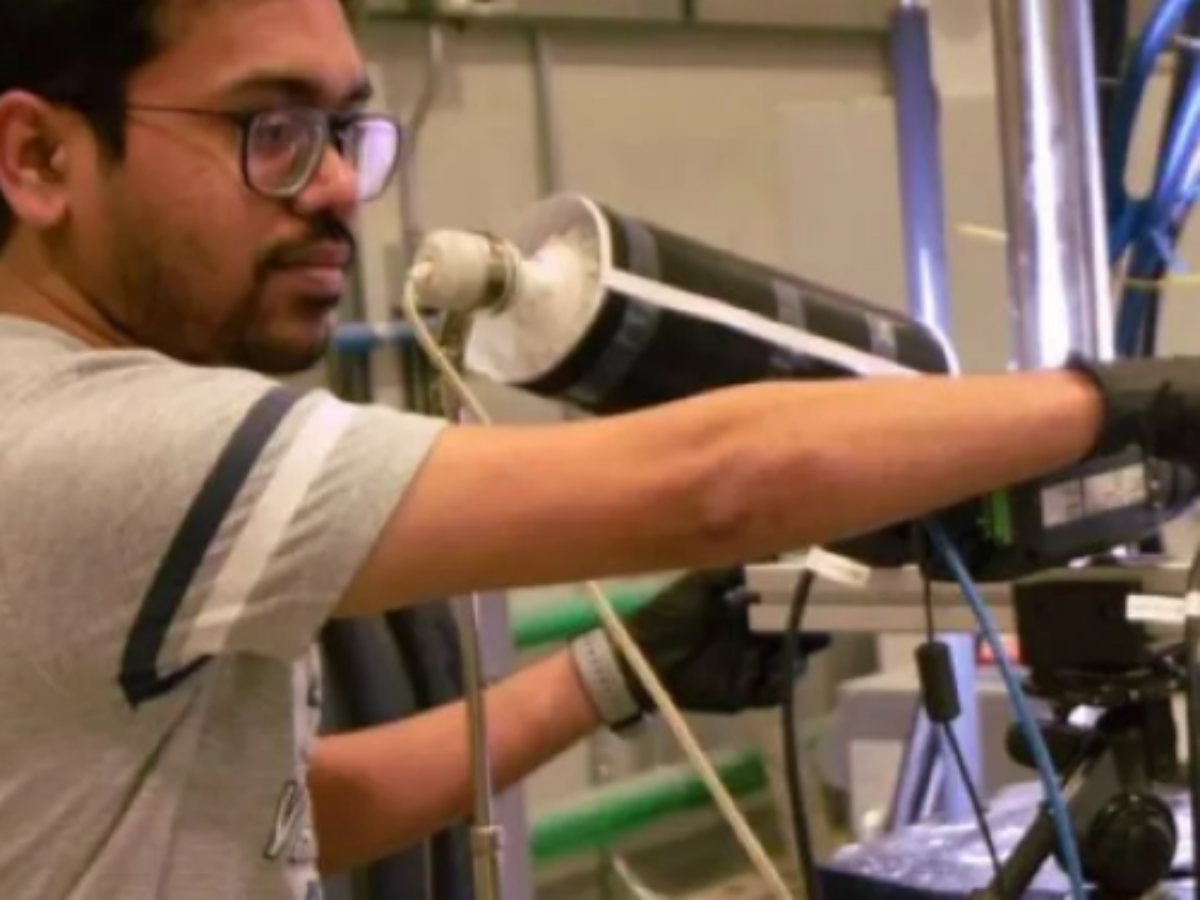

Metal 3D printer manufacturer SPEE3D has opened its first US-based manufacturing facility and applications center at the John Olson Advanced Manufacturing Center (pictured) at the University of New Hampshire (UNH).

The new facility will enable SPEE3D to collaborate more closely with clients in the United States, including the U.S. Department of Defense.

The company celebrated this milestone with a ribbon-cutting ceremony that included SPEE3D leadership, UNH faculty and leadership, and local dignitaries.

SPEE3D will manufacture printers at the new facility, while maintaining its manufacturing headquarters in Melbourne.

The CEO of SPEE3D Byron Kennedy said: “Establishing our first U.S.-based location at the Olson Center brings together a world-class manufacturing center at UNH with SPEE3D’s leading cold spray additive manufacturing technology to a region known for its innovation and advancements.

“Although we are an Australian company, we have partners worldwide and a strong presence in America, so it made perfect sense to expand our footprint to address the needs of our partners.”

The company also will staff an applications centre and work with customers to identify new applications and tailor solutions based on their specific needs, according to a statement.

SPEE3D will also leverage UNH’s resources, facilities, and talent pool to drive additive manufacturing innovation and adoption, while providing technical support for existing and future advanced 3D printing initiatives.

SPEE3D’s new location is located near facilities of the U.S. Department of Defense, the Portsmouth Naval Shipyard (NH), Bath Iron Works (ME), the Army Natick Soldier Research Center (MA), the U.S. Army Research Laboratory (MA), the Naval Underwater Warfare Center (RI), and the Raytheon Technology Research Center (CT).

The Senior Vice Provost for Research, Economic Engagement and Outreach at UNH Marian McCord said: “UNH’s partnership with SPEE3D underscores the vital role that academic and industry collaboration can play in fostering innovation and cutting-edge research.”

Picture: John Olson Advanced Manufacturing Center

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos